A crucial aspect in the development of maneuvering and propulsion systems for ships, as well as rotors for turbines, is the prediction of cavitation phenomena and the associated secondary effects, such as vibration excitation, noise emission, and erosion risk. Particularly, the dynamics and spatial extent of cavitation must be captured as accurately as possible through both experimental and computational methods.

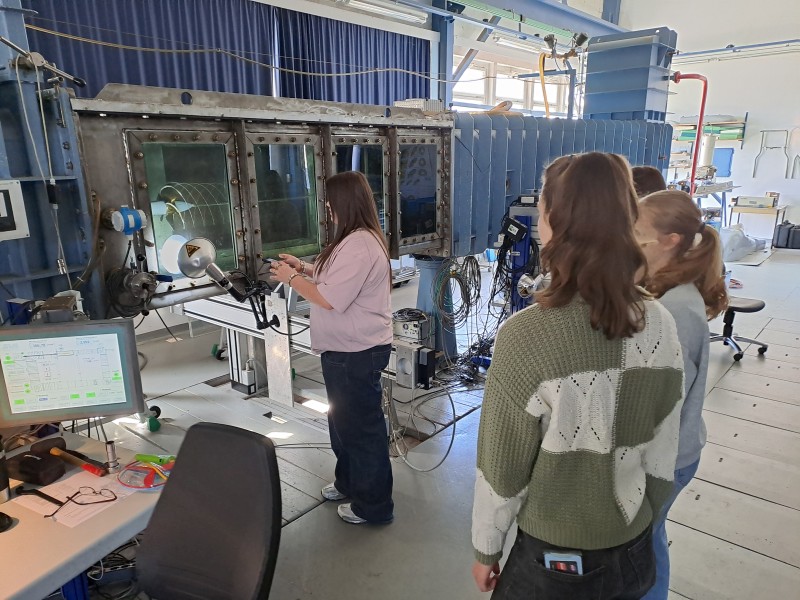

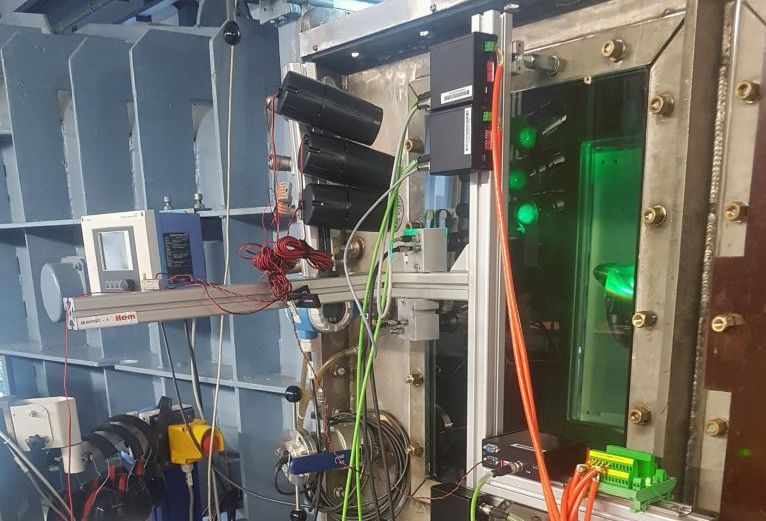

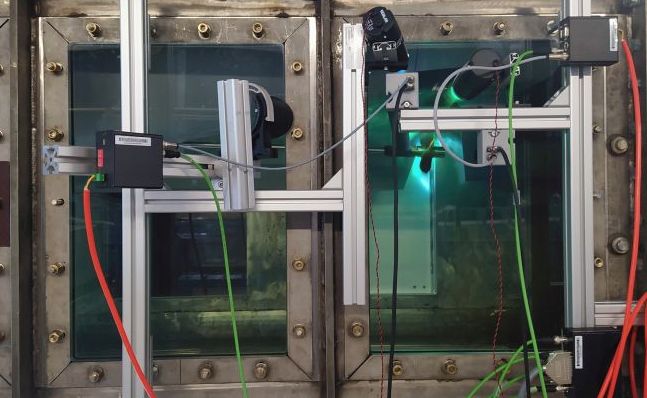

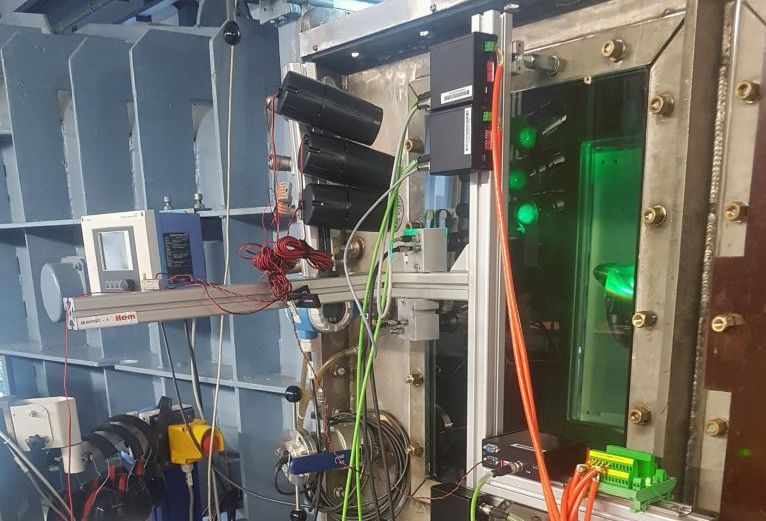

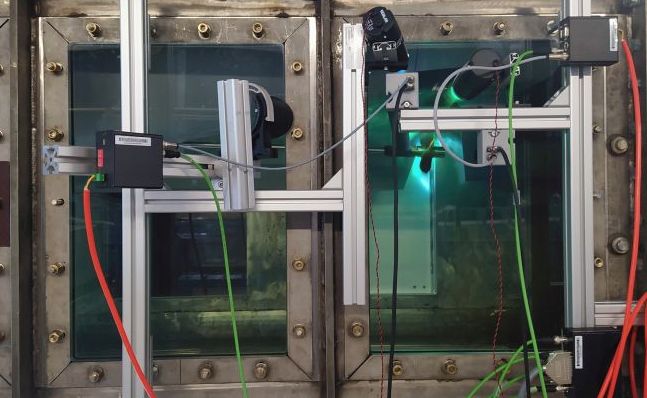

In this context, the Optical Cavitation Inspection System (OCIS) was integrated into SVA’s cavitation research as part of the “R&D Funding Program for Non-Profit External Industrial Research Institutions – Innovation Competence (INNO-KOM)” (Reg. No. IZ 49IZ210009). OCIS includes components such as the KED-Photonics® Nuclei Sizer 300 (based on HDNC technology) for measuring cavitation nuclei concentration, and a synchronized multi-camera and LED lighting system (KED-Photonics® Cavitation Imager 2.1).

Using OCIS, cavitation phenomena are synchronously recorded with multiple cameras and subsequently reconstructed in three dimensions. Image processing techniques are employed to determine the spatial extent of cavitation and the probability of its occurrence. Data on the distribution of nuclei in the water, as well as objective statistics on observed cavitation, form the basis for correlation analyses, which are critical for evaluating cavitation experiments and conducting complex cavitation simulations.

The measurement system was developed through continuous research and development within the collaborative R&D projects KonKav and HiOcav, funded by the BMWi (Federal Ministry for Economic Affairs and Energy). These efforts targeted key challenges in current cavitation research, such as determining the nuclei spectrum in water and resolving the temporal and spatial extent of cavitation. SVA actively participated in these projects, contributed significant foundational work, and gained extensive experience in the application and use of the technology.