Trim optimisation tests have already been carried out as standard procedure since 1970. As a result of the R & D project “Effective Trim Optimisation for Cargo Ships” [1] it has been possible to improve the predicting methods of power savings (calculated trim optimisation) as well as the experimental trim optimisation. The methods have different approaches from a purely statistical analysis of extensive model test series up to CFD simulations of entire trim matrices:

- Prediction of the resistance of the ship for different draughts with or without combinations of various trim states using the resistance method according to Danckwardt and / or the SVA-LSR method

- Formulas for determining the influence of partial discharging and / or trimming characteristic values on the propulsion

- Hybrid procedure: Predicting of resistance and propulsion for partial discharging and / or trimming by coupling parts of the process of resistance according to Danckwardt / SVA LSR method with experimental results

- Trim optimisation through pilot projects (EFD)

- Trim optimisation through CFD calculations (CFD)

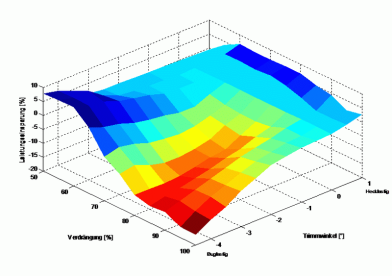

As a result, master and officers may set the optimum trim condition for the ship using the information provided by the methods mentioned above. The 3D contour plot shows an example of the dependence of the power saving on displacement and trim.

Context Related References / Research Projects

[1] Heinke, C.: Effektive Trimmoptimierung für Frachtschiffe, Bericht 4394, Schiffbau-Versuchsanstalt Potsdam GmbH, Juni 2015, Abschlussbericht