Twin propellers

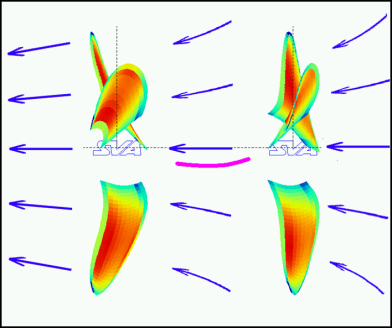

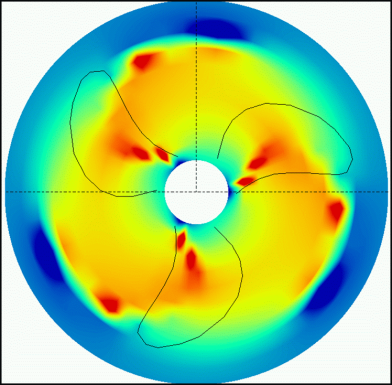

Twin propellers work with a pull and a push propeller with the same rotational direction. The design of the rear propeller places increased demands on the calculation method. Twin propellers should be arranged such that the vortex of the pulling front propeller passes between the wings of the rear pushing propeller. By the contraction of the propeller wash of the pulling propeller, additional water from the sides reaches the pushing propeller.

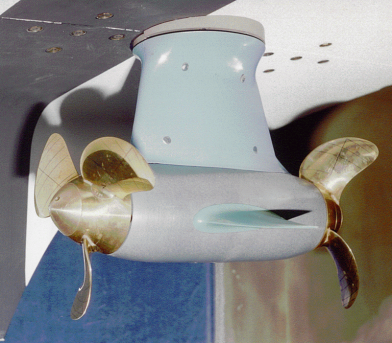

If twin propellers are used on thusters (Schottel Twin Propeller (STP)), or Podded Drives (Siemens Schottel propulsor (SSP)), the housing must be hydrodynamically optimised and provided with guide fins. The twist in the propeller wash of the pulling propeller is partially recovered in this way and influences the inflow to the targeted pushing propeller.

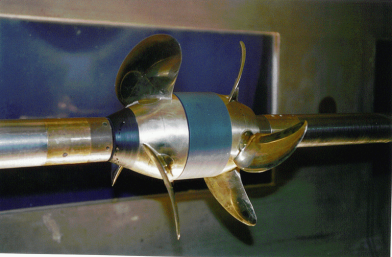

The SVA‘s VORTEX propeller calculation method has been adapted for the design and optimisation of twin propellers [1]. The following photos show examples of the hydrodynamic model and the calculated inflow to a pushing propeller.

Contra-rotating Propeller

Contra-rotating propellers consist of two contra-rotating propellers. Through the reverse rotating propeller, rotational losses can be avoided because the rear propeller can use the rotational energy of the flow which is induced by the forward propeller. In addition, the load is distributed over the two propellers.

The SVA has measuring systems for the study of contra-rotating propeller systems in both the towing tank and cavitation tunnel. In recent years systematic studies of the effect on efficiency of the distance between the contra-rotating propellers and the layout of pods between the contra-running propellers have been carried out.

On behalf of REINTJES, the Fortjes® pod propulsion system was developed [5], [6]. The propulsion system is used especially in planing and semi-planing yachts up to 40 m long and in a power range of up to 3000 kW. The SVA’s VORTEX method was and is used for the design of contra-rotating propellers. Gondola and shaft were completely newly designed to optimally take advantage of the contra-rotating propeller and the pod.

Context Related References / Research Projects

[1] Schulze, R.; Bertolo, G.; Brighenti, A.; Kaul, S.: LUITO Development and Optimisation of the Propulsion System; Study, Design and Tests, PRADS, The Hague, September 20 – 25, 1998

[2] Kaul, S.; Heinke, H.-J.; Abdel Maksoud, M.: Hydrodynamische Optimierung von Podded Drives und aktuelle Anwendungen in der Großausführung (Anwendungsbeispiele SSP), 54. Sitzung des FA „Schiffshydrodynamik“ der STG, Hamburg, 13.09.2000

[3] Edel, K.-O.: Zum Entwurf gegenläufiger Propeller nach der Theorie von Lerbs (77. Mitteilung der SVA), Schiffbauforschung 10 (1971) 5/6

[4] Schmidt, D.: Propulsionsuntersuchungen mit Einzelpropeller und Gegenlaufpropeller am Modell eines Containerschiffes, Schiffbauforschung 14 1/2/1975

[5] Schulze, R.; Weber, A.: Application of the new FORTJES® Z-drive from REINTJES on planing vessels, 11th Intern. Conference on Fast Sea Transportation, FAST 2011, Honolulu, Hawaii, USA, Sept. 2011

[6] Schulze, R.; Weber, A.: The new FORTJES® Z-drive from REINTJES with contra rotating propellers for high speed applications, 11th Intern. Conference on Fast Sea Transportation, FAST 2011, Honolulu, Hawaii, USA, Sept. 2011